Business Situation

The client’s production plant in India relied heavily on manual processes such as real-time tracking of equipment performance, production planning and control, and inventory management. This dependence led to data silos, with each production line operating independently, making it difficult to consolidate and analyze performance metrics across the plant. Machine downtimes were addressed reactively, resulting in unexpected delays, and inventory levels were managed inconsistently. The lack of automated workflows frequently disrupted production schedules, compounding inefficiencies and increasing operational costs.

Recognizing these challenges, the client identified the need for a solution that could deliver real-time visibility into production processes. They envisioned a centralized production management platform capable of automating routine tasks while enabling predictive maintenance to reduce unexpected machine breakdowns.

Their objective was to build a fully integrated, smart production platform that could scale with growing operations while maintaining efficiency, agility, and cost-effectiveness. To achieve this, they required technical expertise in developing advanced production management systems with real-time monitoring and predictive analytics.

After evaluating multiple providers, the client chose Unthinkable for its proven ability to deliver scalable, custom platforms that integrate seamlessly with existing infrastructure. With deep domain expertise and a proprietary architect framework, Unthinkable builds solutions that help accelerate delivery and drive measurable business growth, all with enterprise-grade quality and speed.

Through collaborative brainstorming sessions, the client and Unthinkable defined a comprehensive set of requirements, including:

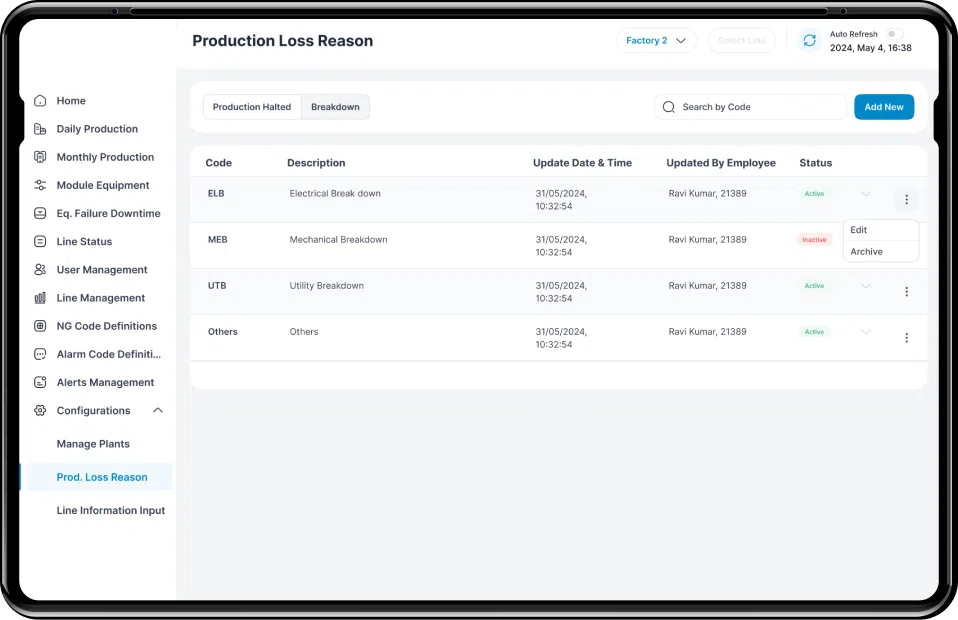

Strategize the overall development lifecycle by recommending the optimal software architecture and technology stack for an IoT-based production management platform.

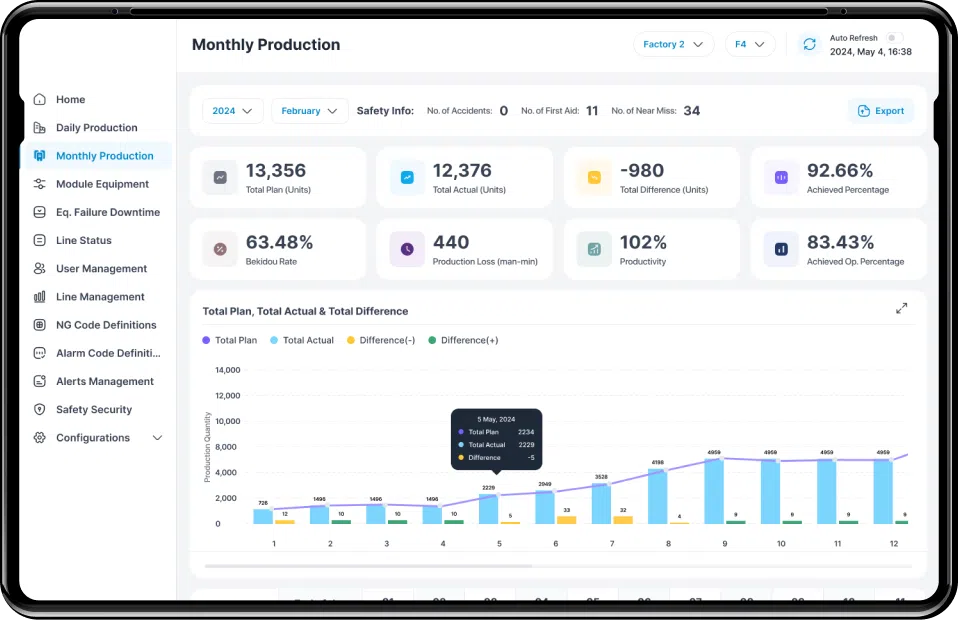

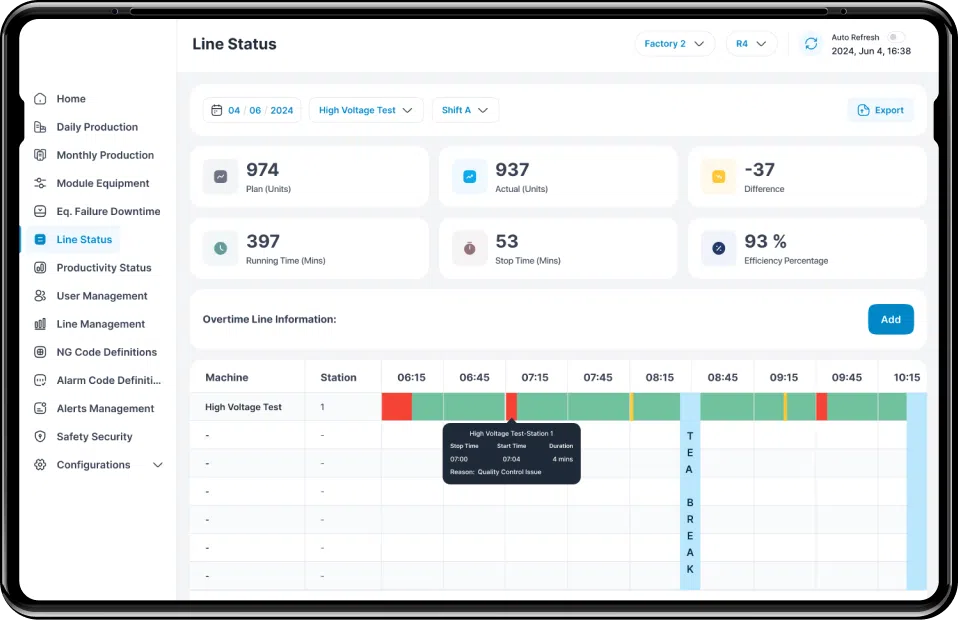

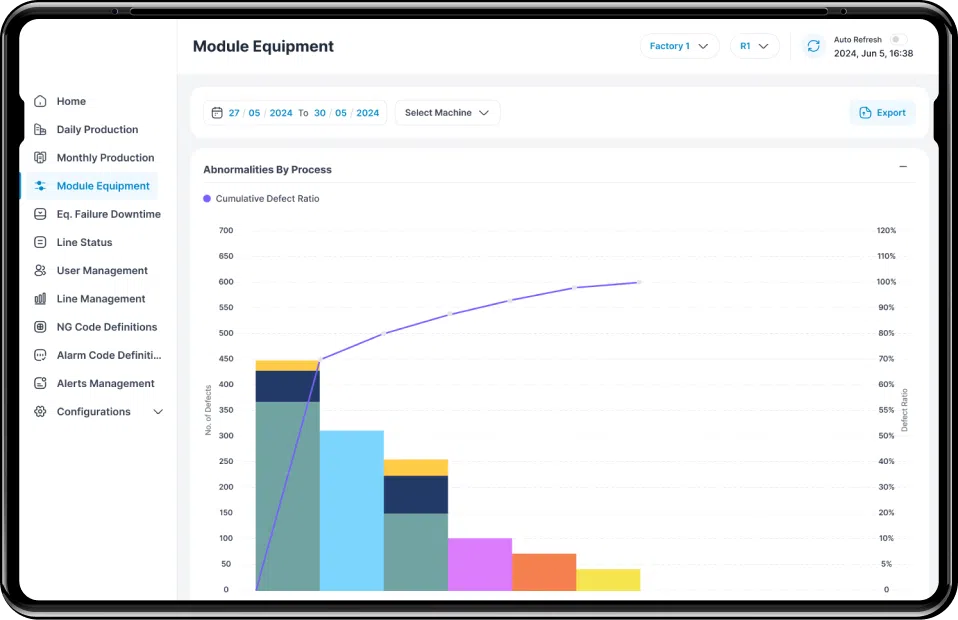

Design a dashboard that aggregates real-time data from all production lines, highlighting performance metrics, machine health, and inventory levels.

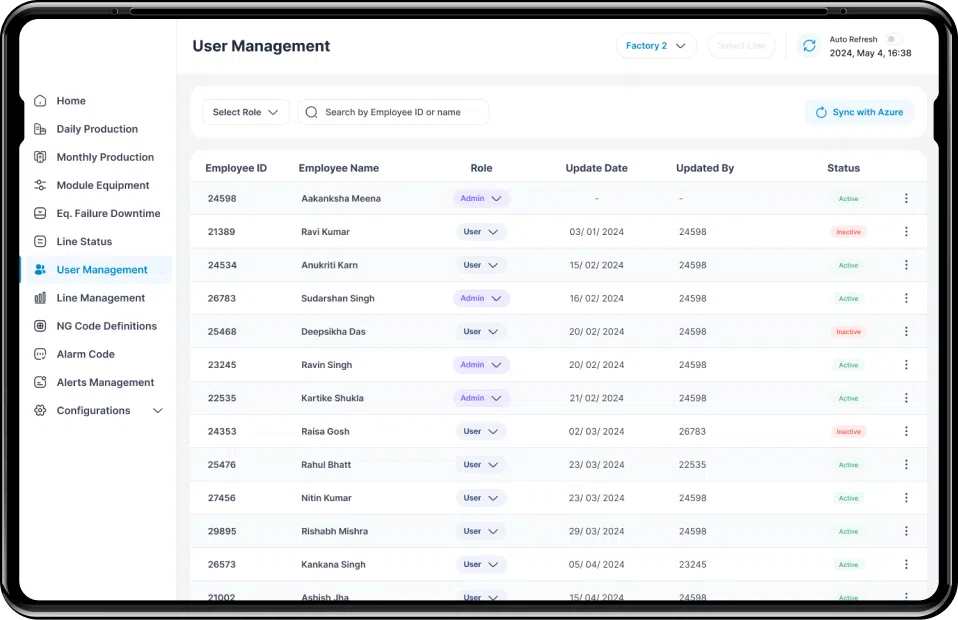

Integrate role-based access control to ensure appropriate access levels based on user roles and responsibilities.

Implement reporting and analytics capabilities to provide real-time insights into plant-wide performance, including machine health, production efficiency, downtime trends, and other KPIs.

Enable mobile access so plant managers and operators can monitor production performance, receive maintenance alerts, and access key metrics.